|

First

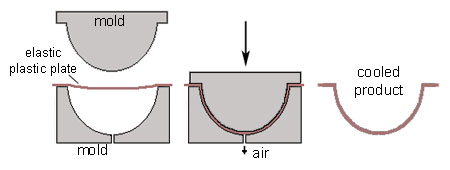

the molds are fabricated individually.

Then we fabricate the products with the thermoforming

process.

During the process the plastic plate is heated, whereby

ist becomes elastic and shapeable.

After that the

elastic plastic plate is sucted on |

|

|

|

the

mold and the form of the muld is transferred to the

plastic plate. By

cooling the plate down the product hardens and keeps the

form of the muld.

Possible further steps of treatment |

| When

the product cooled down, there are several possibilities

to treat it. We can die cut parts or bevel them. Moreover

parts can be varnished. |

|

Possible

steps of treatment are:

- to bevel parts on the CNC milling machine

- to die cut cutaways

- to varnish or to plate the surfaces

- to print on for example advertising slogans

- to splice the product with other parts e.g. by jamming

them or by heat-sealing |

For the fabrication of the products

different plastics can be used. They are available in

different colours and even transparent. Moreover there is

the possibility to utilise plastics with special

attributes.

If you are interested just write us an email and we will

answer your questions concerning the procedure or certain

products!

|